| 1 |

CAPACITY |

Single Trolley

Double Trolley

|

| 2 |

TEMPERATURE |

Depends on Product to be Dried.

Ranging from - 65 degC to 250 degC

|

| 3 |

TYPE OF DRIER |

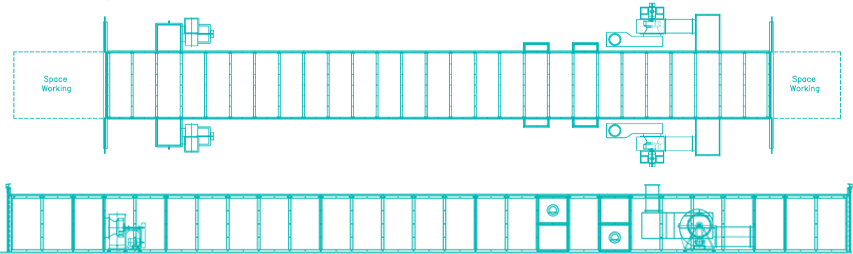

Tray and Trolley Type Tunnel Drier

|

| 4 |

TYPE OF HEATING |

Additional

Can be Dehumidifier Heater, Hot Air Generator - Gas or Solid Fuel,

Thermic Fluid Heater or Boiler as may be.

|

| 5 |

HEAT ENERGY REQUIRED |

800 Kcal/Litre of water @ 80 degC

|

| 6 |

TYPES OF BLOWERS |

Specialised high efficiency blowers

|

| 7 |

AUTOMATION |

Fully Automated with PLC based system,

VFD controlled Motors,

PID controllers and sensors for maintaining consistent parameters

|

| 8 |

ENTRY AND EXIT |

Automated Doors at Entry & Exit ends

|

| 9 |

TROLLEY MOVEMENT |

Step and Repeat Trolley movement

|

| 10 |

PARAMETER CONTROL |

Rh Controlled or Temperature Controlled depending on Product

|

| 11 |

DIMENSIONS |

Continuous or Batch Type as per Requirement.

|